WINTERIZATION/DEWAXING PLANT

Benefits of the Dewaxing Process

This process involves removing waxes and other impurities from crude oil or petroleum products to enhance their properties. Here are some advantages of the dewaxing or winterization process in the refinery:

- Improves flow properties: Dewaxing enhances the fluidity of petroleum products, especially in cold weather conditions, by reducing the cloud point and pour point.

- Enhances product quality: The removal of waxes and other impurities improves the stability, lubricity, and overall performance of the final product.

- Increases profitability: Dewaxing enables refineries to produce high-quality products that can command a premium price in the market, thereby increasing profitability.

- Reduces equipment wear and tear: The removal of waxes reduces equipment wear and tear, thereby increasing the lifespan of machinery.

Overall, the dewaxing process in refinery is a cost-effective way to improve the quality of petroleum products and increase profitability. Its benefits make it an essential step in the production of high-quality diesel, base oils, and lubricants.

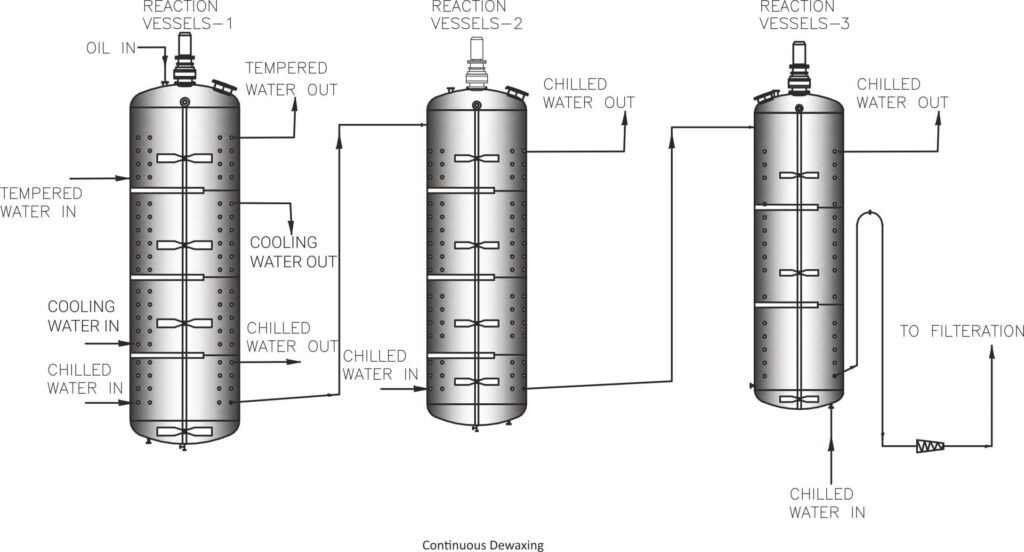

The Dewaxing Process

Here are some essential steps to consider during the dewaxing or winterization process:

- Degumming and Neutralization: The first step is to remove impurities such as phospholipids, metals, and free fatty acids.

- Cooling: The oil is cooled to a temperature of around 10-15°C, allowing for the formation of wax crystals.

- Filtration: The oil is passed through a filter to remove the wax crystals.

- Rewarming: The oil is heated back to its original temperature to ensure that the process does not affect its overall quality.

Overall, the dewaxing process in refinery is a critical step in producing high-quality vegetable oils. The process ensures that the oils remain liquid at low temperatures and can be used in various food applications.