BIO DIESEL PLANT

Culmination of Technology, Skillsmanship,

Knowledge and Experience

BIODIESEL PROCESSING PLANT/BIODIESEL MANUFACTURING PLANT

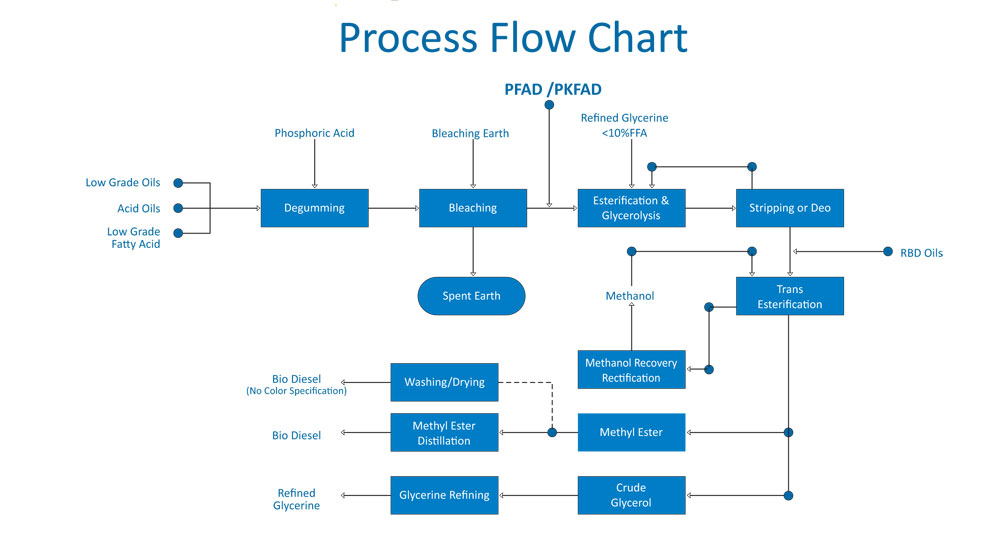

Biodiesel, processed in a biodiesel manufacturing plant or biodiesel processing plant refers to the addition of a methyl /ethyl group to the aliphatic chains in vegetable oils or animal fats rendering them equivalent to the properties of diesel. This is achieved by chemically reacting lipids (e.g., vegetable oil, Fatty acids, animal fat, and used cooking oil) with alcohol (Methyl/Ethyl) producing fatty acid esters either in a Jatropha biodiesel plant, Karanja biodiesel plant, Mahua biodiesel plant, Enzymatic biodiesel, Continuous stirred tank reactor Biodiesel, or a Multi feedstock B100 Biofuel Plant.

Feed Stock

The feedstock for Biodiesel can be categorized into two broad segments, viz:

Low Grade Feed Stock

This includes used cooking oil, Acid Oil, Low-grade Fatty Acid, High FFA vegetable oil.

High Grade Feed Stock

This includes Low FFA vegetable oil (CPO, Soya, Sunflower, etc.), Palm Stearin, High-Grade Fatty Acid & Tallow.

The glycerine phase will be discharged from the bottom of the separation tank.

Blend

- Blends of biodiesel and conventional hydrocarbon-based diesel are products most commonly produced in a biodiesel manufacturing plant in Mehar and distributed for use in the retail diesel fuel marketplace. Much of the world uses a system known as the “B” factor to state the amount of biodiesel in any fuel mix produced in a Multifeedstock B100 Biofuel Plant.

- 100% biodiesel is referred to as B100

- 20% biodiesel, 80% Petro diesel is labeled B20

- 5% biodiesel, 95% Petro diesel is labeled B5

- 2% biodiesel, 98% Petro diesel is labeled B2

Mepl Advantage

- As a top biodiesel production plant supplier and biodiesel plant manufacturer, the plant provided by Mehar is capable of manufacturing Bio-diesel conforming to EU (EN 14214) and BIS 15607:2005 standards.

- Extremely low Sulphur content; which helps to check Air Pollution.

- As one of the best biodiesel manufacturing plant manufacturers and suppliers in Pakistan, the solutions provided by the company better industry benchmarks in ash & moisture content, total contaminations, and carbon residue indicators.

Mepl Advantage

Mepl is among the best tocotrienol manufacturers and biodiesel plant suppliers in India and abroad. Mepl has earned the reputation of being one the best biodiesel plant suppliers in Pakistan and abroad by offering the following advantages:

- Any Vegetable oil / Used Cooking Oil / by-products of refinery and animal fats can be processed

- Single plant with Multi Feed Stock options

- Very Low Soap Formation

- Reduced Catalyst Consumption

- Conversion Rate is very high

- Low Methanol Consumption

- Pharma Grade Glycerin

- High Quality Bio Diesel as per International Standards

- Highly Energy Efficient Plant

- Ulity Consumpon Very Low

- Waste Water is very low

- Emission Standard very low

- Fully Automated PLC Operated Plant

- 100 % customized Plant available in Batch Type & Continuous Type

Highlights

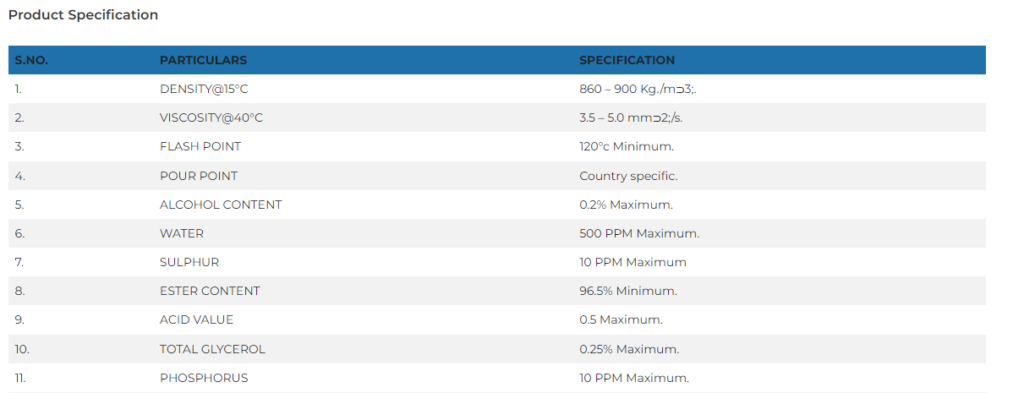

The Mepl Biodiesel manufacturing plant in Pakistan and abroad is capable of manufacturing Bio-diesel conforming to EU (EN 14214) and BIS 15607:2005 standards.

- Extremely low Sulphur content; which helps checking Air Pollution.

- Beers industry benchmarks in ash & moisture content, total contaminations and carbon residue indicators.

There are several methods for producing biodiesel, each with its own set of advantages and disadvantages. The most popular methods include the transesterification process, the esterification process, and the supercritical methanol process. Ultimately, the best process for biodiesel production depends on factors such as cost, availability of resources, and environmental impact. So, it's not a one-size-fits-all situation. But hey, with a little bit of research and some experimentation, you'll be on your way to producing high-quality biodiesel faster than you can say "renewable energy".

Mepl is the largest manufacturing company of biodiesel plants in India. Their expertise lies in designing and building state-of-the-art biodiesel plants that are capable of producing high-quality biodiesel using a range of feedstocks. The biodiesel making process involves various stages, including feedstock preparation, esterification, and transesterification, which are all carefully controlled to ensure the highest quality biodiesel output. Mepl also provides turnkey solutions and after-sales support to ensure seamless operation and maintenance of their multi feedstock biodiesel plant. As one of the leading biodiesel suppliers in Pakistan, Mepl has made significant contributions to the growth of the biodiesel industry in the country.

It is difficult to declare a single biodiesel company as the best for setting up production plants in Pakistan, as there are several factors to consider such as location, availability of resources, and financial feasibility. However, companies with experience in the biodiesel making process and a proven track record in India may be more suitable for this endeavor. Mepl is one such company that has been involved in the development and implementation of biodiesel production plants in India. Nonetheless, thorough research and analysis of various biodiesel companies, their technologies, and their success rates in India would be necessary before making a decision.