PILOT PLANT

Culmination of Technology, Skillsmanship,

Knowledge and Experience

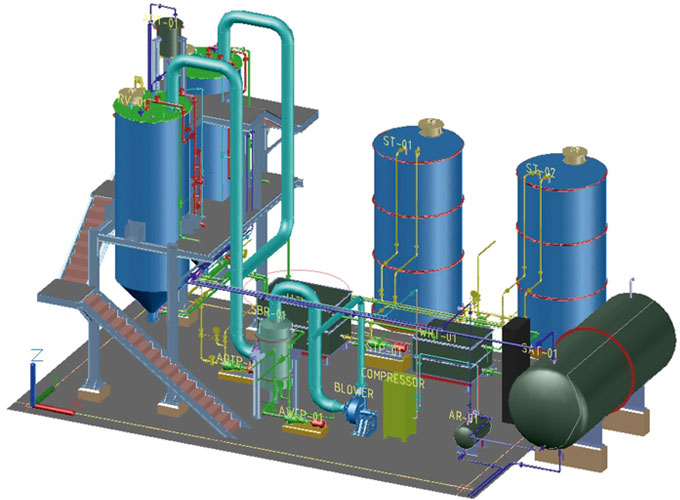

Mepl is one of the best Pilot Plant manufacturers in Pakistan and abroad. We are delivering since 1961 in the Oil & Fats sector by manufacturing and supplying customized, highly energy efficient, Innovative, Turnkey Projects ,plant and equipment’s for Oil extraction, pretreatment & refining, modification of oil & fat, value added specialty products, oleo chemicals or waste products recoveries, Bio Diesel & Filters.

Mepl recognizes the fact that R&D is an integral part of any manufacturing company who wish to launch a new product in the market. For the said purpose, Pilot Plants are required for ascertaining the desired product parameters, taste, composition, look & feel etc. before going for mass production.

Mepl is one of the top Pilot Plant suppliers in Pakistan and abroad providing Pilot plant for the following:

- Vegetable oil Refinery

- Fractionation

- Hydrogenation

- Bio Diesel

Mepl Process Engineers can provide Pilot Plant for Hydrogenation/ Pilot Plant for Biodiesel from the capacity of 50 Kg/ Day to any capacity as desired. The Pilot Plants offered by Mepl are 100% customized and can be made skid mounted or can be set up in the R&D Shed of the customer.

Apart from the aforementioned Pilot Plants if any other Pilot Plant is desired with respect to Vegetable Oil Refining & Oleo Chemicals, Mepl will consider the same & shall extend all cooperation.

Multiple trains

The reduced staffing that automation makes possible, coupled with the enormous expansion in data work-up and mining capabilities offered by today’s computers will promote the increased use of multiple trains. This will increase the complexity of pilot plants as well as their support and maintenance requirements — but the added productivity and effectiveness will outweigh the higher costs. Such setups may consist of multiple trains on the same unit or multiple copies of a single unit, depending upon the organization’s requirements. They will provide not only traditional data but also more-in-depth analytical and operational results for use in evaluation and design.

Unit size

The days ofthe size of pilot plants shrinking every generation are probably realistically approaching an end. However, the use of very small high-throughput “pilot plants” (which actually are more akin to very complex experimental equipment) will increase. These high-throughput units will handle much of the screening currently performed more slowly and expensively in standard small pilot plants. Highly automated pilot plants then will run the promising leads at a more realistic and scalable range, to evaluate synergistic effects and operations at transient conditions as well as process conditions more realistic of a plant environment. The combination, when properly applied, will produce a greater number of high quality leads faster, and provide a means to screen these for the next generation of process or product improvements. Modeling will continue to augment and validate pilot-plant operations and, in the always symbiotic relationship, pilot plants will continue to augment and validate modeling.